From planning to distribution, all in Seoul… Ensuring luxury-level production quality and speed.

Building a Korean-style agile supply chain that combines functionality, quality, and consumer feedback.

Global apparel manufacturing has traditionally been a network dominated by large corporations, but in recent years, rising indie brands have been leading the way. Image = ASRV’s “RELENTLESS PURSUIT” collection

Korea has long been recognized as a production hub synonymous with stability and quality. However, even when many international brands contract with Korean companies, actual mass production takes place in low-wage regions like Vietnam, Bangladesh, and Indonesia. Global apparel manufacturing has been dominated by overseas networks centered around large companies like Sae-A, Hansae, and Hansol.

In recent years, the supply chain landscape has shifted, with priorities shifting from low cost to agility and speed in responding to trends. Rising, independently operated, fast-growing indie brands are particularly leading this trend. Their streamlined decision-making structures and distinct brand identities allow them to respond quickly to changes.

# Rapisin, realizing ‘agility’ by making Seoul a global hub

Based in Seoul, Rapishin has established an operational structure that integrates the entire process from planning to design, production, and distribution into a single flow.

A prime example is La Piscine, a women’s clothing brand launched in Milan, Italy, in 2024. Just one year after its launch, La Piscine relocated its entire production process—from product planning and sample production to mass production and logistics—to Seoul, garnering industry attention.

This decision was a strategic shift aimed at operating the entire process, from planning to distribution, more quickly and flexibly. Korea, with its skilled manufacturing infrastructure, influence as a global trend-setter, and expedited logistics network, was a natural fit for Rapisin’s growth strategy.

Co-founders Giovanni Muracchini and Alice Moraschini cited Korea’s “complete fashion ecosystem, combining a network of skilled artisans, rapid trend adoption, and a digital platform-based distribution environment” as their reason for choosing the country. They particularly emphasized that the garment sampling, sewing techniques, and meticulous finishing meet the standards of European luxury brands, enabling them to reliably execute the sophisticated details required for seasonal collections.

By establishing a base in Seoul, Lapisin has established an operational structure that integrates all processes, from planning and design to sample production, mass production, and distribution, into a single flow. This allows for new product planning and sample validation to be completed in just a few weeks, real-time collaboration with overseas showrooms, buyer consultations and feedback, and immediate adjustments to order and inventory data.

Furthermore, through major logistics hubs, including Incheon and Busan, the company simultaneously covers the Asian, European, and North American markets. Partnerships with global express carriers like DHL and FedEx enable rapid international delivery. After-sales service is also handled directly from the Korean headquarters, ensuring prompt response to product repairs, exchanges, refunds, and customer inquiries, solidifying its reputation as a “trustworthy brand” among overseas consumers and buyers.

This agility has paid off. Since its release in February, Rapichine’s Fall/Winter 2025–2026 capsule collection has been stocked by over 30 major multi-brand retailers, including Printemps in Paris, Harvey Nichols in Hong Kong, Beymen in Istanbul, and La Rinascente in Milan. La Rinascente will host a month-long, 60-square-meter pop-up store on its fourth floor in September, co-locating with Isabel Marant and Zimmermann.

# ASRV’s “Three-Way” Strategy: Functionality, Quality, and Consumer Feedback

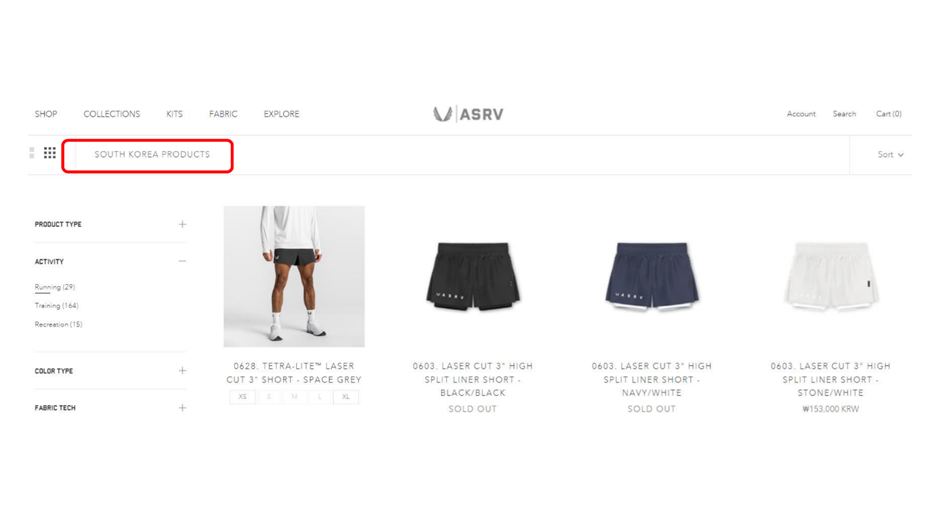

ASRV operates a dedicated ‘South Korea Products’ category on its official online store, highlighting the quality and value of products made in Korea.

Headquartered in Carlsbad, California, premium sportswear brand ASRV is rapidly expanding its global presence through collaborations with Korean manufacturers. Founded in 2014 by Jay Barton, the brand has garnered attention for its unique designs that combine performance sportswear with a streetwear aesthetic, and in 2020, it was named to Forbes’ “30 Under 30” list.

Since its launch, ASRV has experienced rapid growth. Sales increased 80% from $10 million in 2019 to $18 million in 2020, and the brand’s Instagram followers surpassed 1.32 million in 2022. This represents approximately 34% of the followers of global sportswear giant Lululemon, demonstrating a strong online presence for a brand of its size.

The key to growth has been a strategy that has prioritized Korea as a key production base. High-performance fabrics like Tetra, Tetra Lite, Kinterra, and Aerosilver, sourced from companies like Hyosung, Taekwang, and Woozoo Global, are used for waterproofing, windproofing, and water-repellent treatment, as well as post-processing for high elasticity and lightweighting. Korean manufacturing’s ability to maintain consistent quality even through complex cutting and multi-stitching processes underpins global consumer trust.

Quality control is implemented throughout the entire process, from design to delivery. Domestic testing agencies verify the durability, color fastness, and sewing strength of fabrics and accessories. During the production phase, sample wear tests are conducted to verify that the design intent matches the performance of the finished product.

We also have a system in place to quickly incorporate consumer feedback into product improvements. We review feedback collected through Instagram, Discord, and our own platforms and incorporate it into the next batch. For example, if there are frequent requests for pocket depth or crotch length for a particular pair of pants, we immediately relay these requests to our Korean production line for design changes.

Rising overseas indie brands are establishing synergy by establishing systems in Korea to enhance quality, functionality, and respond quickly.

This agile, consumer-centric operation further solidifies the trusting relationship with Korean manufacturing. For the 2017 Fall/Winter season, ASRV launched a capsule collection emblazoned with the Korean phrase “RELENTLESS PURSUIT,” incorporating its respect for Korean manufacturing into its product design. Currently, the company operates a dedicated “South Korea Products” category on its official online store, emphasizing the quality and value of products made in Korea.

An industry insider commented, “ASRV is a prime example of maximizing synergy by combining Korea’s high-quality manufacturing capabilities with the planning and marketing strategies of a global brand.”

Rapisin and ASRV have combined Korea’s trend-leading expertise, precise production quality, and rapid response to the global market to establish a “Korean-style agile fashion supply chain,” differentiating itself from the existing mass-market, low-cost global production model. The agile model involves a structure that iterates planning, production, and launch in short cycles, enabling agile response to changing trends.

Industry experts believe this approach is highly applicable to luxury and premium brands, as it “enables both rapid trend adaptation and high-quality production.” One global retail consultant emphasized, “In the past, luxury brands adhered to a slow fashion calendar, but now they must move faster to keep pace with the pace at which customers experience trends or they will fall behind in the competition. The Korean agile model could be the answer.”

This stands in stark contrast to the six-month or longer collection cycles of traditional European luxury brands. This differentiation is expected to lead to an increase in the number of niche luxury and premium streetwear brands relocating to Korea.